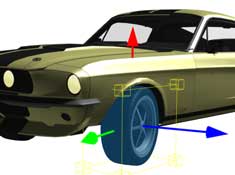

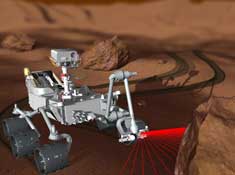

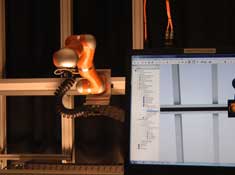

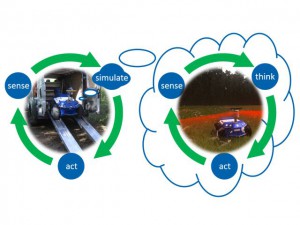

“Virtual Commissioning” aims at the setup and initial programming of complex automation systems based on digital model and methods, particularly 3D simulation and rendering. Its purpose is the integrated planning, implementation, controlling and continuous improvement of all essential production processes and resources in connection with the real systems. The objective of this research area is the development of universal planning and simulation tools for automation technology in order to simulate complete production lines with all their integrated components like robots, programmable logic controllers (PLCs), feeding devices, transport facilities and sensors. Building on this: Layouts can be optimized; robots and control programs can be developed; as well as reachability and collision checks can be conducted among others. The simulation of all motion sequences, the handling processes and the interaction with the periphery ensures that the results are transferable to the real cell.

Particularly approaches in Visual Programming are able to offer intuitive access to the programming of complex automation systems. Here, the research at MMI aims at the development of customized visual programming concepts for various scenarios such as robot programming and virtual commissioning of industrial processes based on multi agent systems.