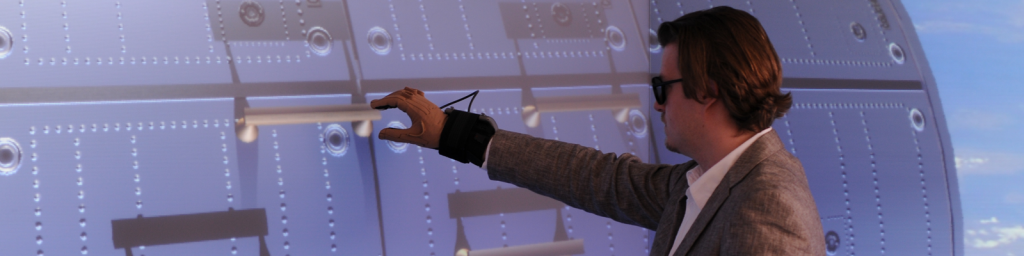

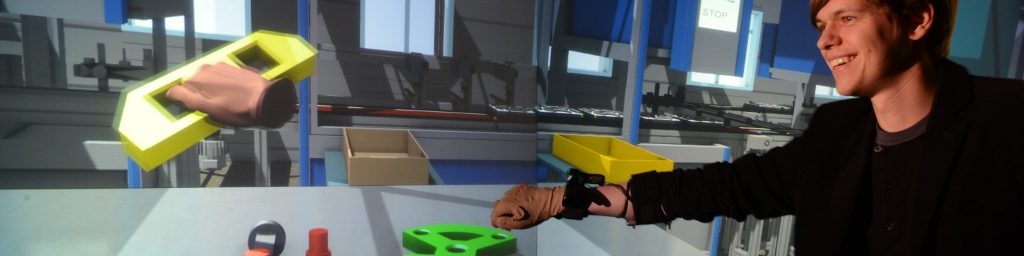

In AsTeDiF, an assistance system is being developed to support the machine operator in operational training and learning processes on a tufting machine. The basis for this are Experimentable Digital Twins (EDT) of the textile machine, product, work tools and machine operator. With AsTeDiF, negative consequences of errors in the real world are predicted and prevented in good time by the EDT. Instead, the consequences of the operator’s actions are visualized by predicting the EDT’s behaviour using AR glasses. This allows the operator to learn from mistakes and benefit from the proven high learning effectiveness of errors. The vision is to enable the operator to operate a tufting machine safely and purposefully by using the assistance system at the workplace for two weeks.

The IGF project “Development of an assistance system for textile machines with didactic use of errors for operational training and learning processes as well as retooling, maintenance and repair processes using the example of the tufting machine (AsTeDiF)” 23479 N of the Research Association Forschungskuratorium Textil e.V., Reinhardtstraße 14-16, 10117 Berlin was funded by the German Federal Ministry of Economics and Climate Protection via the AiF as part of the program for the promotion of joint industrial research and development (IGF) based on a resolution of the German Bundestag.