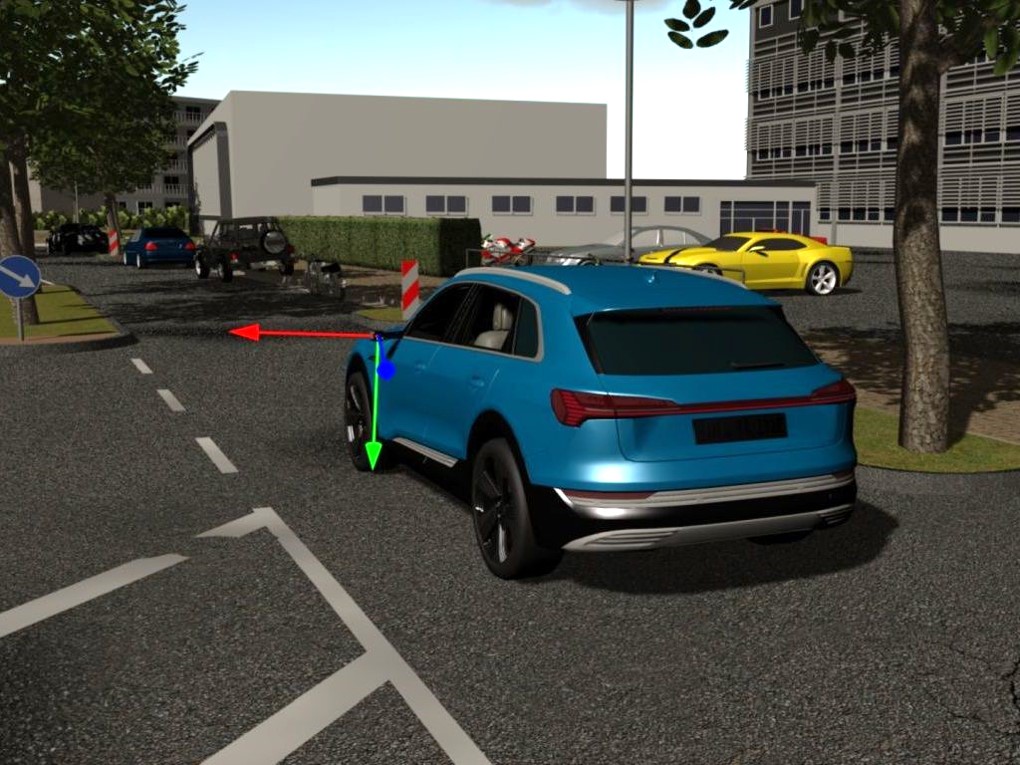

The objective of the DeLas project is the significant reduction of process development and production ramp up times for the automated assembly of laser systems by bridging the gap between product development and automation control. The objective of DeLas is to develop and integrate methods and software tools for implementing complex sensor-guided handling and alignment processes into a software toolchain which covers the relevant steps of automated laser assembly. Based on virtual production environments, virtual and real commissioning of processes will grow closer together in DeLas and strengthen the role of offline programming. On the one hand, the virtual production environments organize the access to simulation features and geometric as well as optical models. On the other hand, they organize the access to real hardware, thus allowing for continuous, model- and simulation-based refinement and automated control of processes.