The development of new sensor hard- and software components within the ViTOS-Testbed is the first step in the life cycle of optical sensors. Subsequently, the individual hardware components are manufactured, tested and integrated into the surrounding system. This is precisely where ViTOS-II comes into play.

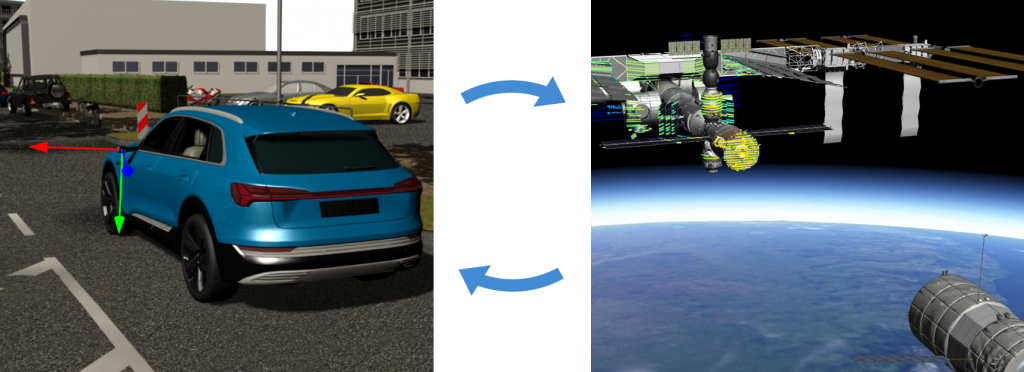

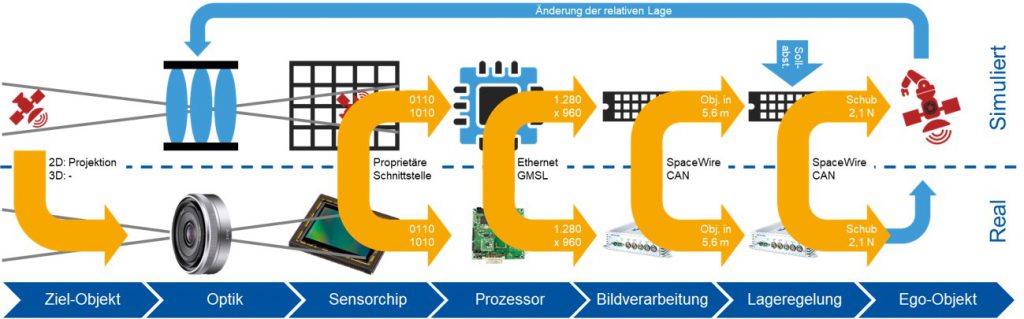

In ViTOS-II, processes are researched and the necessary components are developed, which provide a seamless transition from the simulated prototype to the real system in a real environment. Following the ideas of virtual commissioning and gradual substitution from the industrial manufacturing sector, ViTOS-II enables the successive replacement of individual simulated elements by corresponding emulated or real components and thus a continuous transition from the simulated to the real system.

For this purpose, components of Experimental Digital Twins (EDT) of real sensor data processing systems are developed whose structures allow a 1-to-1 representation of the closed loop. Through the use of natural – as used and often standardized in reality – interfaces, switches between simulation and reality are provided at any point of the data processing chain realizing the novel approach of Hybrid Twins.

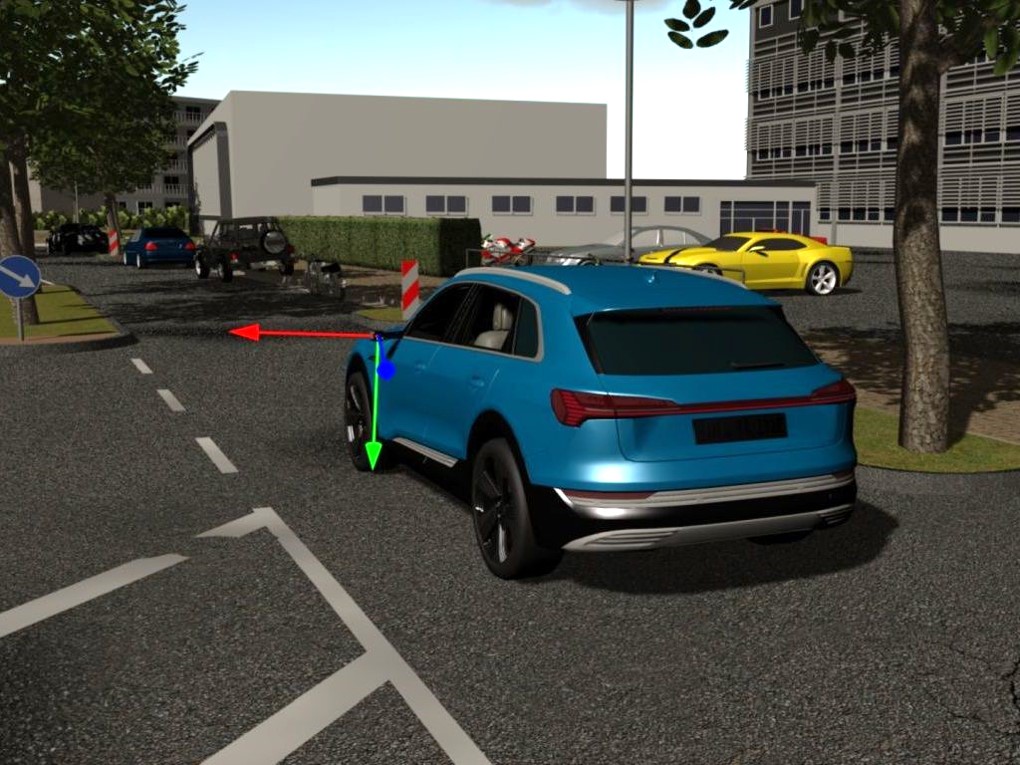

Here, the ViTOS-Testbed and the associated processes shall be seamlessly integrated in the development processes of the participating industrial players from the Space and Automotive sectors. Afterwards, the validation of the research results shall be validated under using the pre-defined reference scenarios “LiDAR-Based Rendezvous & Docking” and “Intelligent Camera Monitor System”. With the objective of developing generic models and processes that provide a physically-based simulation of the sensor types LiDAR and camera as well as a bidirectional technology transfer between Space and Automotive. ViTOS-II picks up on this complexity and researches solutions to overcome it.